Specific design needed?

Although Nautilus Marine Service is specialized in the production of pressure housings made of glass, we can further advise on high-quality turned and milled parts in complex geometries for pressures vessels in general. In addition to widespread stainless steel, we also support non - ferrous and Titanium alloys as well as high performance plastics.

Advantages

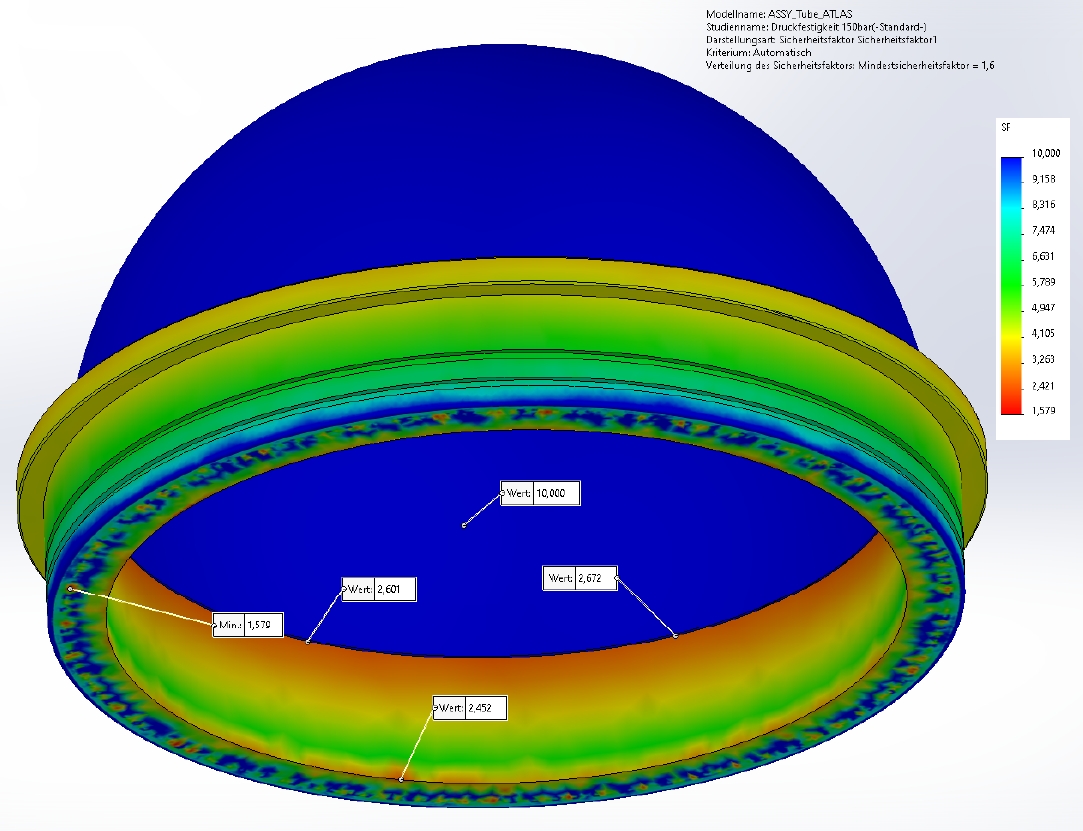

During the design phase of components and assemblies, strength and lifetime calculations are performed. These calculations will be carried out in accordance with applicable regulations, standards and accepted literature.

With the help of the finite element analyses, the actual load conditions can be made visible and multi-axial stress conditions as well as the resulting elastic and plastic deformations become obvious. Due to this, components and assemblies can then be structurally adapted or optimized in detail.

A comprehensive concept

The designs we create are always evaluated in terms of its technical feasibility, economic success and existing risks. Our services in this regard can be scaled and include all necessary technical documentation such as drawings, reports or parts lists as well as detailed requirements related to manufacturing.