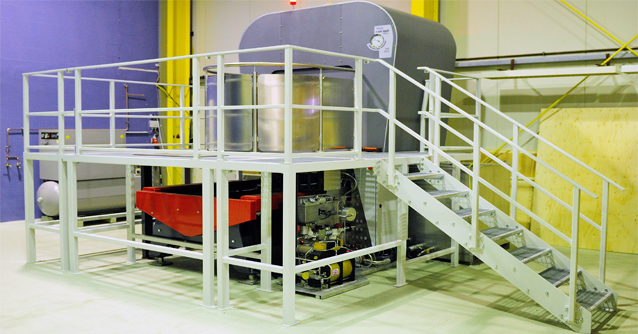

Datawell, the producer of the reknowned waverider buoys offer a few interesting inventions for their buoys.

The newly developed Compact Air Temperature (CAT4) option integrates the HF antenna, flashlight and an air temperature sensor. Power switch are now standard on all Waverider buoys. The new 5.2.0 relase of the well-proven Waves4 has been released. There is a new GPS based light detection system for all Waverider buoys. There are also new safety lines, harder rubber chords and rubber cords with swivel on both ends available. Extensive information are available in this Datawell Newsletter.